There are five connection structures between the

steel tube and the tube plate in heat exchangers. The connection of the

steel tube to the tube plate is a crucial part of shell-and-tube heat exchanger design. It involves significant processing work and requires every connection point to ensure media leakage prevention and withstand media pressure.

The three main connection structures for the tube and tube plate are as follows: (1) Expansion, (2) Welding, and (3) Expansion-welding combination. These structures have inherent characteristics and are influenced by production conditions and operational techniques during processing.

01 Expansion:

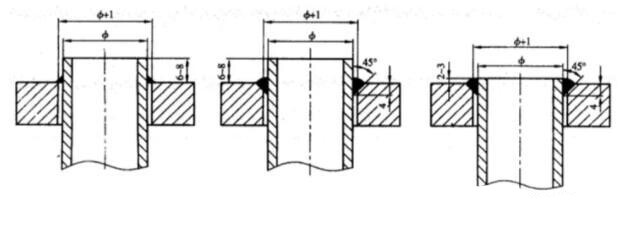

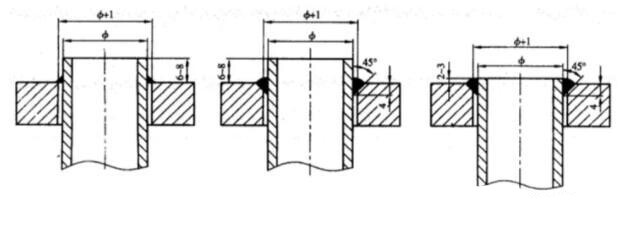

Expansion is used when inter-shell media leakage will not result in adverse consequences. The structure is simple, and tube repair is easy. However, residual stress exists due to plastic deformation during expansion, which diminishes sealing and bonding effectiveness as temperatures rise. Therefore, this structure is limited by pressure and temperature. Generally suitable for pressures P0 ≤ 4 MPa, with a maximum temperature for residual stress disappearance varying depending on the material. For carbon steel and low-alloy steel, the operational temperature can reach up to 300°C under low pressure conditions. To improve expansion quality, the tube plate material must be harder than the tube end, ensuring expansion strength and tightness. Surface roughness and gap size between the tube hole and tube also affect expansion quality, with a roughness requirement of Ra12.5. Longitudinal grooves are not permitted on sealing surfaces to prevent leaks.

The tube holes come in two types: smooth holes and grooved holes. Smooth holes are used when the pulling force on the expansion is minimal, while grooved holes are used when the pulling force is significant. Grooved holes improve resistance to pulling forces and enhance sealing. The number of grooves depends on the tube plate thickness: one groove for plates less than 30 mm thick, and two grooves for plates 30 mm or thicker. Expansion depth varies depending on the tube plate type and material.

02 Welding:

Welding between the tube and tube plate is widely used due to its simplicity. Tube holes do not require grooving, and the roughness requirement is low. Welding provides high strength and pull-out resistance. Welded areas can be repaired or replaced easily compared to expansion. The shear section of the weld seam should be at least 1.25 times the tube section.

Stainless steel tubes are generally welded to the tube plate regardless of pressure or temperature. Special attention is needed to prevent blockages during welding, particularly for small-diameter tubes. Grooving around the tube hole was common but is now generally avoided.

03 Expansion-Welding Combination:

This structure is suitable for high-pressure systems, combining the strengths of expansion and welding. It involves either expanding before welding or welding before expanding, each with its advantages and challenges. Pre-expanding enhances weld seam fatigue resistance but requires careful cleaning to prevent weld defects. Pre-welding eliminates this cleaning requirement but demands precise positioning during expansion to avoid damaging the weld seam.

Different types of welding (e.g., sealing or strength welding) and expansion (e.g., strength or sticking expansion) can be combined based on requirements. Welding provides strength, while expansion eliminates gaps to prevent corrosion. The height of the welded seam should be 1–2 mm to maintain expansion strength. Welding after expansion is suitable for high-pressure heat exchangers, with the weld seam height set at 2.8 mm.

04 Internal Bore Welding:

Internal bore welding forms a butt joint structure between the tube hole and shell-side tube. It optimizes stress distribution and reduces edge stress. It is particularly useful for heat exchangers prone to stress corrosion or gap corrosion.

However, internal bore welding requires high welding skill and is challenging to repair if defects occur. Strict adherence to construction parameters is necessary to ensure welding quality.

05 Explosive Expansion:

Explosive expansion is a new technique that combines explosion expansion with sealing or strength welding. It offers high joint strength and increased efficiency. Unlike other methods, no lubricants are used during explosive expansion, resulting in cleaner surfaces for welding. Explosive expansion utilizes explosives to deform the tube rapidly, ensuring tight contact with the tube plate. It is suitable for thin-walled tubes, thick-walled small-diameter tubes, and large-thickness tube plates.

Explosive expansion offers high pull-out resistance and minimal tube deformation. It is effective for repairing leaks at the tube end.