Abstract: In water supply projects, the use of steel pipe welding technology is not only essential to construction safety but also directly determines the long-term stability of the entire water supply system. To fully realize the core value of steel pipe welding, construction personnel must start by managing the inspection and acceptance of steel pipes, carefully select and control the welding process, and maintain strict quality control throughout the entire construction phase. This paper examines common technical challenges encountered during welding to ensure the safety and reliability of public water supply systems. Focusing on a specific water supply project, the study carries out steel pipe welding in strict accordance with the “Specifications for Manufacturing, Installation, and Acceptance of Pressure Steel Pipes for Hydropower and Water Conservancy Projects” (DL/T 5017—2007).

The significance of steel pipe welding technology in water supply projects cannot be underestimated. At every stage of construction, project teams must account for the impact of various external factors on welding performance. Based on the pipeline’s geometric dimensions, weight, and other parameters, appropriate control measures should be implemented to ensure the safety of the water supply project and provide more reliable water services to surrounding communities.

The Lintan County Central Area Water Supply Project (Phase I) is a general contracting project located in Lintan County, Gansu Province. Managed by the Lintan County Yintao Rutan Project Construction Management Office, the system comprises four main components: water intake, water purification, water transmission, and water distribution. The water intake component, serving as the starting point of the entire system, consists of two main sections—the intake hub and the intake pumping station—responsible for extracting raw water. The extracted raw water is then transported to a water purification plant for treatment. The water transmission system, a critical link between water intake and final distribution, spans 12 km and delivers treated water to designated supply points. The system includes a 5,000 m³ elevated water tank and two booster pumping stations. The primary booster station is relatively small but has been upgraded to a Class IV structure, while the secondary booster station is medium-sized with a Class III structural rating, both ensuring the stable operation of the entire water transmission system.

A 25-ton truck crane is used for lifting operations in this project. Before each operation, crane operators must strictly follow operating procedures and perform a thorough inspection, with particular attention to the condition of the wire rope. If any abnormalities are detected—particularly wear on the wire rope—the operation must be stopped immediately and may only resume once all issues have been fully resolved and the equipment is confirmed to be safe and operational. For pipe alignment, a hydraulic alignment device matched to the pipe diameter is employed as the primary tool. The inner walls should remain flush, with allowable misalignment not exceeding 10% of the pipe wall thickness, and the alignment gap limited to a maximum of 3 mm. If the pipe roundness deviation exceeds 5D/1000, correction should be carried out using a 100-ton mechanical jack, and the weld joint must not be forcibly closed. Welding must be suspended if the pipe diameter deviation exceeds acceptable limits. These measures help ensure the highest possible first-pass weld quality.

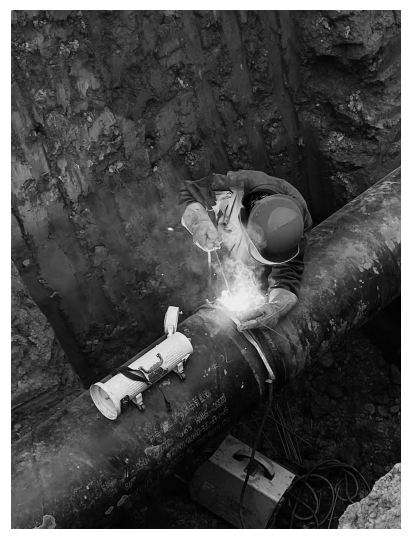

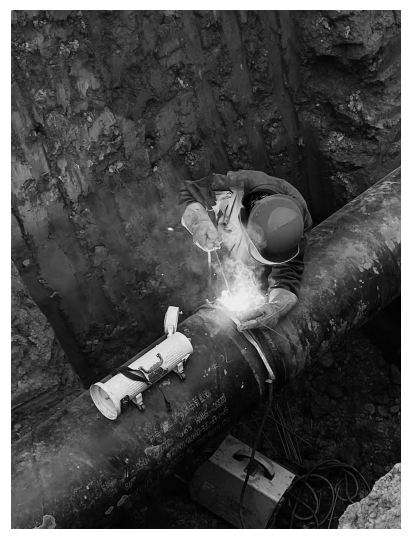

In steel pipe welding, spot welding is employed to temporarily connect pipe sections and prevent misalignment during subsequent full welding operations. During spot welding, strict control of weld length and spacing is essential. Under normal conditions, each spot weld should be 5–10 cm long, with a spacing of approximately 20 cm, as shown in Figure 1. After completing spot welding, construction personnel must continuously monitor the welding process to prevent any shifting or vibration of the pipe assembly. In this project, E6010 Φ4.0 cellulose electrodes are used as the primary welding consumables. These electrodes offer stable welding performance and improve construction reliability while fully meeting the requirements for steel pipe welding.

Figure 1 Spot Welding Construction

An inverter-type DC arc welding machine serves as the primary welding equipment for this project. Because of the project’s remote location, a 50 kW generator is also provided to ensure a reliable power supply in remote areas or under unstable grid conditions. Cellulose electrodes E6010 (Φ4.0) are used as the welding material, making them an ideal choice for steel pipe welding. The pipe wall thickness on site is 12 mm. Before welding, workers grind both ends of the tack welds to completely remove slag and properly prepare the joint for continuous welding. After striking the arc at a single point, welding should proceed continuously. The welding speed must be carefully controlled, maintaining a rate of 15–30 cm/min. If the wind speed exceeds 8 m/s, appropriate wind shielding measures must be implemented. Welding should be carried out from top to bottom to minimize weld deformation. Care must be taken to avoid mechanical damage to the pipe surface. For localized scratches or grooves, grinding may be performed with a minimum grinding slope of 1:3. The grinding depth should not exceed 10% of the pipe wall thickness at the affected location and must be limited to a maximum of 2 mm to maintain a smooth weld surface. After completing the root pass, welders must thoroughly clean the root and repair any visible defects. Any spatter on the bevel should be carefully removed to ensure a neat and uniform weld appearance. Welding current and arc voltage should be selected according to the pipe wall thickness and electrode specifications. In this project, the welding current is maintained at 75–90 A and the arc voltage at 26–30 V, ensuring an optimal balance between weld penetration and bead formation.

When installing steel pipes, the effects of welding on the connected pipe sections must be carefully considered. An inverter-type DC arc welding machine is used in conjunction with a 50 kW generator to ensure a stable power supply. Before welding, thorough preparation is necessary, including the selection of appropriate welding materials. The weld surface is cleaned using an angle grinder to remove slag, oil, and other contaminants, thereby improving weld fusion quality and minimizing the risk of welding defects. Flux-cored, self-shielded welding wire (JC-29 Nil, Φ2.0) is used as the primary filler material. A continuous welding method, combined with downhill welding, is employed to ensure uniform weld formation and improve the overall quality of the joint. To enhance welding efficiency, multiple welding machines are operated simultaneously, with two welders working from the 12 o’clock position downward, performing welding in both the 6 o’clock upward and 6 o’clock downward directions. During welding, the current and voltage must be strictly controlled. When striking or breaking the arc, welders should promptly adjust the parameters to maintain a current of 180–240 A and a voltage of 19–20 V, effectively preventing defects such as incomplete fusion and undercut.

Before welding begins, personnel must perform a thorough inspection of key materials, including welding electrodes, welding wire, and flux. Welding electrodes must be free of damage, cracks, oil contamination, and rust. Welding wire must be free from corrosion, bending, or deformation to ensure stable current flow during welding. The flux should also be carefully inspected to ensure it has not deteriorated. Additionally, the shielding gas used for welding must meet specified purity and dryness standards to enhance protection during welding and prevent oxidation or other weld defects. Construction personnel must strictly control the purity, mixing ratio, and humidity of the shielding gas. Regular testing with high-precision gas analyzers is necessary to ensure that the gas consistently meets project specifications. Gas mixing must be performed using a professional gas-mixing device. During welding operations, the condition of the welding electrodes must be carefully monitored. If any abnormal conditions occur—such as overheating of the electrode coating, excessive smoke, or significant arc deviation—welders must immediately replace the electrodes to prevent compromising weld quality.

During steel pipe installation in water conservancy projects, inspecting weld quality is of critical importance. A qualified weld must be uniform and free of defects on the surface or in the heat-affected zone, including cracks, lack of fusion, porosity, slag inclusions, spatter, or arc craters. The weld surface must be level with or above the base metal, and weld reinforcement should be maintained within 0–3 mm. To ensure the consistency and reliability of non-destructive testing (NDT), all inspection personnel must possess valid technical qualification certificates. These certificates must be issued by authoritative organizations—such as water conservancy industry associations, quality and technical supervision departments, or non-destructive testing societies—and must correspond to the specific responsibilities of the inspection personnel. After completing visual inspection and any necessary grinding, every weld must undergo 100% all-position radiographic (X-ray) inspection to leverage the penetrating power of X-rays and detect potential internal micro-defects. However, inspection responsibilities are distributed differently among the various parties:

- The construction unit conducts 20% self-inspection.

- The supervision unit carries out 30% random inspection.

- The owner or client unit performs 50% random inspection.

This multi-tiered inspection system guarantees thorough and reliable quality control of welds throughout the project.

Before the pipelines arrive at the construction site for unloading, the project’s quality inspection team must work closely with the supervising engineer to perform a thorough and detailed visual inspection. This ensures that the delivered pipelines meet design specifications and prevents construction delays caused by material defects. The inspection should include checks for surface rust, scratches, dents, deformations, and other visible defects. All identified issues must be thoroughly documented in the inspection and acceptance records, ensuring full traceability for subsequent welding and quality control activities. Steel pipe welding is a critical process in water supply construction, with its quality directly impacting the overall safety and operational reliability of the project. Therefore, personnel involved in welding operations must have relevant experience with stainless steel and carbon steel pipelines and hold valid qualification certificates. Before performing actual welding work, welders must pass a rigorous professional assessment to ensure their technical skills meet both project and industry standards.

At the construction site, all personnel must wear approved safety helmets before entering the work area to prevent accidental head injuries. Workers are strictly prohibited from wearing slippers or other unsafe footwear. Personnel working at heights must use safety nets, harnesses, and other personal protective equipment to reduce the risk of falls and ensure overall construction safety.

Before developing emergency response plans, construction management personnel must adhere to scientific principles and conduct a comprehensive assessment of potential hazards, including natural disasters such as landslides or collapses, as well as disruptions caused by human factors. The responsibilities of all key emergency response personnel must be clearly defined to ensure that rescue operations are conducted in a timely and orderly manner during emergencies. Due to temperature fluctuations during construction, workers must remain vigilant against the risk of burns. Appropriate protective equipment—such as heat-resistant gloves and masks—should be used to prevent skin injuries from hot surfaces or objects. Additionally, essential emergency rescue facilities must be readily available on-site to ensure a rapid response in the event of burns or other accidents, whether providing immediate first aid or coordinating external assistance. Each shift leader must hold a safety meeting before construction begins to assess the day’s safety risks, maintain accurate records, enhance workers’ safety awareness, and improve overall emergency preparedness.

The management and quality control of welding materials for steel pipes in water supply projects are highly complex processes. To effectively address material and quality control challenges during welding, it is essential to carefully select materials, store and use them properly, and enforce strict quality control throughout the entire process. These measures contribute to improved weld quality and enhance the overall performance of the project. The experience gained from this project offers valuable guidance for similar engineering projects and contributes to the advancement of steel pipe welding technology in water conservancy works.