Abstract: Austenitic stainless steel pipelines are extensively used in the nuclear and petrochemical industries because of their excellent corrosion resistance and long service life, making them suitable for the safe transport of a wide range of liquids and gases. However, the performance of the same pipeline material can vary significantly under different operating environments, such as acidic or alkaline conditions, cryogenic temperatures, and high-temperature service. During pipeline construction, fittings such as tees and elbows are required to ensure proper system connectivity, and their manufacturing standards and service requirements must be strictly adhered to according to the design specifications. This paper investigates the causes of recurrent cracking at the welded joints of stainless steel pipeline fittings that occurred during the commissioning and operation of an industrial pressure pipe in a specific project. The findings serve as a reference for analyzing and preventing similar failures in future applications.

After about one month of operation, cracks and leaks appeared at the welded joint of a 48 mm austenitic stainless steel tee installed in an outdoor hydrogen pipeline in a specific project. After timely replacement and repair, a second tee fitting in the same system also developed similar cracks and leaks at its weld joint. Further inspection revealed that multiple welds within the pipeline system exhibited cracking defects. In response to these failures, the project’s technical team conducted a systematic investigation, examining factors including material selection, the properties of the service medium, welding procedures, and inspection and testing methods.

The design drawings specify S321 stainless steel for the pipeline. Both S321 and S316 are commonly used austenitic stainless steels in industrial applications and possess the characteristic properties of stainless steel. S321 is designated as 06Cr18Ni11Ti, whereas S316 is designated as 022Cr17Ni12Mo2. Their chemical compositions are presented in Table 1.

Table 1. Chemical Composition (Mass Fraction, %) of S321 and S316 Stainless Steels

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Ni

|

Ti

|

Mo

|

|

S321

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.035

|

≤0.030

|

9.00–12.00

|

≥5×C, ≤0.70

|

—

|

|

S316

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.035

|

≤0.030

|

10.00–14.00

|

—

|

2.00–3.00

|

As shown in Table 1, the contents of Si, Mn, P, and S are essentially identical for both materials. The most significant difference lies in their alloying elements: S321 contains titanium (Ti), while S316 contains molybdenum (Mo). These differences in type and content of alloying elements result in markedly different intrinsic material properties. Molybdenum promotes grain refinement and greatly enhances resistance to acid and alkali corrosion, making S316 more suitable for demanding service environments. Titanium, as a strong stabilizing element, enhances the steel’s microstructural stability by inhibiting chromium carbide formation, reducing susceptibility to intergranular corrosion, and improving weldability. Therefore, although both S321 and S316 are austenitic stainless steels, their differences in chemical composition, microstructure, and performance indicate that their suitability for hydrogen service may not be the same. The most suitable material should be selected according to the specific operating conditions and service environment of the pipeline.

The pipeline in this project transports hydrogen, with an operating temperature ranging from −30 to 30 °C and a maximum pressure not exceeding 1.4 MPa. Although hydrogen is non-toxic and non-corrosive, it is extremely flammable and explosive. The standard GB/T 29729—2022, Basic Requirements for Safety of Hydrogen Systems, explicitly specifies S316 and S316L as commonly used metallic materials for hydrogen service, whereas S321 is not included. Therefore, from a safety standpoint, low-carbon S316L should be the preferred choice for hydrogen systems with specific operating conditions and media characteristics. Before on-site construction, all relevant standards and technical specifications should be carefully reviewed, and construction must be conducted strictly in accordance with these requirements. Any discrepancies between the applicable standards and the design drawings should be promptly identified and addressed.

Although cracking was observed in the pipeline welds, it occurred specifically at the branch connections of the tees. Therefore, the quality and suitability of the tee components themselves must also be evaluated. Tees are common pipe fittings, and industrial pressure pipelines impose stringent requirements on the strength, ductility, and toughness of materials used in pressure-bearing components. Upon arrival at the site, each batch of materials shall be inspected, clearly identified, and accompanied by the appropriate quality certification documents. These documents shall include inspection and test results in accordance with applicable standards and shall ensure full traceability. Stainless steel pipe fittings are generally manufactured through cold-working processes such as drilling, drawing, and flanging. Cold working may result in pronounced work hardening. With increasing hardening, material toughness deteriorates, thereby increasing the susceptibility of the component to fracture under external loading. During operation, hydrogen gas induces dynamic forces within the pipeline, which act on the tee fittings and result in impact loading. Welded joints are inherently weaker regions, and long-term exposure to such dynamic loading significantly increases the risk of crack initiation and propagation. For tees delivered to the site, inspection shall not be limited to appearance and nominal wall thickness; particular attention shall be given to measuring the thickness of stress-bearing regions. The shoulder area of the tee and its surrounding regions experience relatively high stress concentrations and are therefore more susceptible to failure. Here, cracking was observed at the branch connection weld rather than at the tee shoulder, demonstrating that the tee fitting itself complied with qualification requirements. Furthermore, when evaluating weld cracks at tee joints, the influence of gravity on overhead pipelines over prolonged operation should also be considered. The proper arrangement of expansion compensation devices and the correct positioning of pipe supports are critical factors influencing welding integrity and long-term service performance.

When welding Φ48 mm stainless steel pipes, three methods are typically used: full GTAW, SMAW, and a hybrid approach with GTAW for the root pass and SMAW for fill and cap passes. Considering the small pipe diameter and 3.5 mm wall thickness, full GTAW ensures high efficiency, consistent weld quality, and good surface appearance; therefore, a WPQ was established for this method. During field construction, full GTAW was performed per the approved WPS, employing argon shielding on both the weld’s front and back sides. On-site radiographic inspections, however, showed that many welds failed to satisfy the acceptance criteria, largely as a result of inadequate process quality control.

(1) Pre-welding Preparation

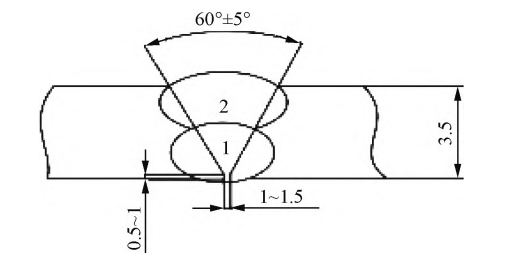

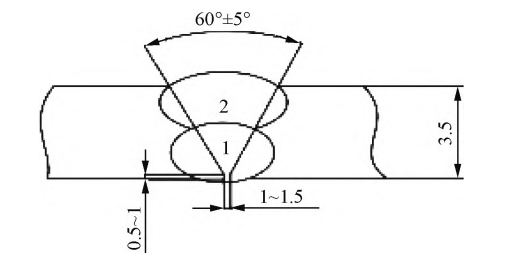

A V-shaped groove was adopted. Before assembly, oil, oxides, and other contaminants on the pipe and fitting bevels, as well as adjacent surfaces that could negatively affect weld quality, were thoroughly removed. The groove dimensions were controlled as follows: gap 1–1.5 mm, root face height 0.5–1 mm, and groove angle 60° ± 5°. Once the assembly position was established, tack welds were applied to hold the joint in place. Owing to the small pipe diameter, precise alignment control was required to achieve a flush root. For tees or pipes exhibiting wall thickness deviations, the surfaces were ground to ensure consistent thickness or a flush root prior to assembly, preventing radiographic indications that might complicate inspection and assessment. Following assembly, the weld joint was masked. One pipe end was sealed with a sponge held in place by argon tubing and steel wire, and the other end was sealed with water-soluble adhesive tape to facilitate effective back purging. A schematic diagram of the pipe beveling configuration is shown in Figure 1.

Figure 1. Schematic diagram of pipe beveling

(2) Argon purging before welding.

Before welding, the pipe interior shall be purged with argon. Once complete air displacement is achieved, the argon flow rate shall be reduced as appropriate, or small vent holes may be provided in the paper tape to ensure continuous argon circulation while avoiding excessive flow and internal pressure effects. Excessive argon flow may interfere with the cooling and solidification of the molten weld pool, causing defects such as porosity, gas entrapment, and lack of fusion, which ultimately degrades weld root quality. To satisfy the project requirements for 100% radiographic inspection and Level I acceptance, adequate pre-welding preparation and effective protection of the weld root during full argon arc welding are essential. The TIG welding torch supplies front-side argon shielding to isolate the tungsten electrode and molten weld pool from air, preventing oxidation and ensuring stable weld pool quality. However, inadequate argon purging of the pipe interior allows air to come into direct contact with the weld root. When the root metal is in a molten, high-temperature state, it readily reacts with oxygen, leading to oxidation and unacceptable welding defects. In such cases, the weld must be removed and rewelded.

(3) Quality Inspection During Welding

According to the project’s testing requirements, welding procedure qualification specimens must be prepared. Accordingly, each weld must be purged with argon on both the front and back sides as described above and carried out strictly in accordance with the parameters specified in the WPS. Detailed welding parameters are provided in Table 2.

Table 2 Welding Process Parameters

|

Number of Layers

|

Welding Method

|

Polarity

|

Filler Material

|

Wire Diameter (mm)

|

Welding Current (A)

|

Arc Voltage (V)

|

|

Root/Pass

|

GTAW

|

Positive

|

ER321

|

2.0

|

90–100

|

10–15

|

|

Fill/Cap

|

GTAW

|

Positive

|

ER321

|

2.0

|

100–110

|

10–15

|

During root pass welding, the fluidity of the weld pool and the fusion between the base metal and filler material on both sides of the bevel shall be continuously monitored. If incomplete fusion is detected, welding shall be halted immediately, and the defective area must be ground prior to resuming welding. When performing welding over tack welds, the existing weld metal shall be completely ground or adequately thinned to allow full remelting. Failure to properly prepare the tack weld pool before remelting can cause localized overheating, leading to weld bead formation on the backside or incomplete fusion, which may result in defects such as slag inclusions or porosity. As argon purging was not applied during the tack weld at this location, the area must be ground to ensure proper weld quality. Upon completion of the root pass, the weld shall be carefully inspected for visible defects, including porosity and cracks. Through-cracks originating at the weld root require immediate corrective action. Experienced welders may use a higher current in subsequent passes to remelt minor defects such as porosity. During welding, the current must remain within the specified range to avoid excessive heat input.

The penetrating cracks identified in this project can be attributed to the following factors:

Improper welding technique: The welder failed to adhere to the specified two-pass welding procedure, attempting to complete the weld in a single pass with high current and large-diameter wire, which caused localized deformation and residual stresses.

Interpass temperature control: Although the welding procedure was followed, the interpass temperature was not adequately controlled. For stainless steel, the interpass temperature shall not exceed 150 °C. Welding the second layer immediately after the first, without allowing sufficient cooling, can cause overheating, oxidation along grain boundaries, and intergranular cracking.

Pipeline stress distribution: Pipeline stresses are generally managed through the use of supports, hangers, and expansion compensation devices. In the present design, no compensation device was incorporated. Consequently, the tee joint experienced increased gravitational stress due to its own weight and the influence of adjacent valves. Stress concentrates in structurally weak areas, especially at the rounded transition of the tee shoulder and at the weld, posing a long-term fatigue hazard. The accumulation of stress and cyclic strain ultimately led to weld cracks, which progressed to fractures and leaks, underscoring the effect of external design factors on crack initiation and propagation.

(3) Non-Destructive Testing

Radiographic testing (RT), a commonly employed non-destructive technique for weld inspection, allows for the evaluation of weld internal quality. On radiographic films of austenitic stainless steel welds, common linear defects include weld root misalignment and lack of fusion, whereas point defects primarily comprise porosity and slag inclusions. The quality of welds shall be assessed in accordance with the designated inspection level to determine compliance with applicable requirements. Following welding of stainless steel, pickling and passivation shall be performed to remove oxides generated during the welding process. The treatment restores a bright metallic finish and establishes a thin, firmly adhering protective film on the weld and heat-affected zone. The surface modification shifts the metal’s electrode potential positively, resulting in the formation of a passive layer that safeguards the weld against corrosion.

Material Selection for Different Environments

For pipes of identical material and specifications used in different environments, the material’s safety and performance under the applicable operating conditions shall be thoroughly assessed. Materials deemed unsuitable for a particular environment shall not be used without proper approval. In this project, the design documentation allows the use of S321 pipes for the transport of hydrogen, a highly flammable and explosive gas. However, due to its molybdenum (Mo) content and enhanced corrosion resistance, S316L is the preferred material for this application.

On-Site Acceptance and Proper Use of Pipe Components

In accordance with GB/T 12459—2017, the 45° arc transition zone at the tee shoulder shall have a thickness equal to 1.5 times that of the pipe wall. For this project, the pipe wall thickness is 3.5 mm. Skilled technicians shall coordinate with inspection personnel to perform on-site acceptance of all materials. The quantity, specifications, quality certificates, and material certificates shall be individually verified. Manufacturers of pressure pipeline components must possess the requisite qualifications. Components supplied by unqualified manufacturers shall be rejected. The chemical composition of stainless steel materials shall be verified through spectral analysis. On-site acceptance shall additionally confirm that the material certificate meets the relevant standard requirements, providing a basis for assessing re-test qualification. Following cold forming, martensitic stainless steel tee fittings shall undergo solution treatment to enhance material properties. Solution treatment reduces grain spacing, refines the grain structure, enhances performance, and minimizes the risk of defects, including cracks.

Reasonable Design to Reduce External Forces on the Pipeline

Stress within the pipeline can be managed and relieved by the use of compensation devices, and gravitational effects can be mitigated by installing supports that evenly distribute loads and reduce the impact of external forces. The quantity, type, and arrangement of supports shall be determined according to applicable specifications to achieve optimal stress distribution.

Welder Qualifications and Welding Quality Control

In pressure pipeline welding, welders are essential to maintaining weld quality. Welders shall undergo professional training, successfully pass examinations, and hold a valid special operation qualification certificate to carry out welding work within the authorized scope and throughout the certificate’s validity period. Competence in argon arc welding, combined with sufficient hands-on experience, is crucial for ensuring high-quality welds. For welds subject to 100% flaw detection, welders shall possess both certification and sufficient experience and skill. Although argon arc welding yields a visually smooth weld surface, defects frequently develop at the weld root or internally, remaining invisible without inspection. All identified defects shall be corrected at the weld root. Welding small-diameter pipes presents greater challenges compared to large-diameter pipes. Welders shall strictly comply with process requirements, encompassing pre-welding preparation, welding process control, and post-weld self-inspection. Radiographic testing shall be performed only after visual inspection verifies that no surface defects are present. Compliance with process qualification procedures and correct back-side argon purging substantially enhances the probability of inspection acceptance.

Industrial pipeline installation shall satisfy safety, performance, and economic requirements throughout all stages, from material selection to operational use. The successful installation of pipelines relies on professional expertise throughout all stages: from on-site material acceptance and review of technical documentation, to support fabrication and assembly, initial pipe alignment and welding, non-destructive testing, pressure and leak testing, and final purging. Thorough inspection and supervision at every stage are critical for ensuring project quality. The installation of industrial pipelines is a series of interdependent processes, and each step must be carefully executed, regardless of schedule constraints. Quality control shall be maintained by dedicated on-site personnel, and all procedures must be executed with strict attention to detail to ensure both the reliability and safe operation of the pipeline system.